autronic

Member

Hi.

Been a while since i have been around but, just as I thought I was out I get dragged back in.

A friend of mine is building a kit car, a cobra mk4 replica from Gardner Douglas gdcars.com

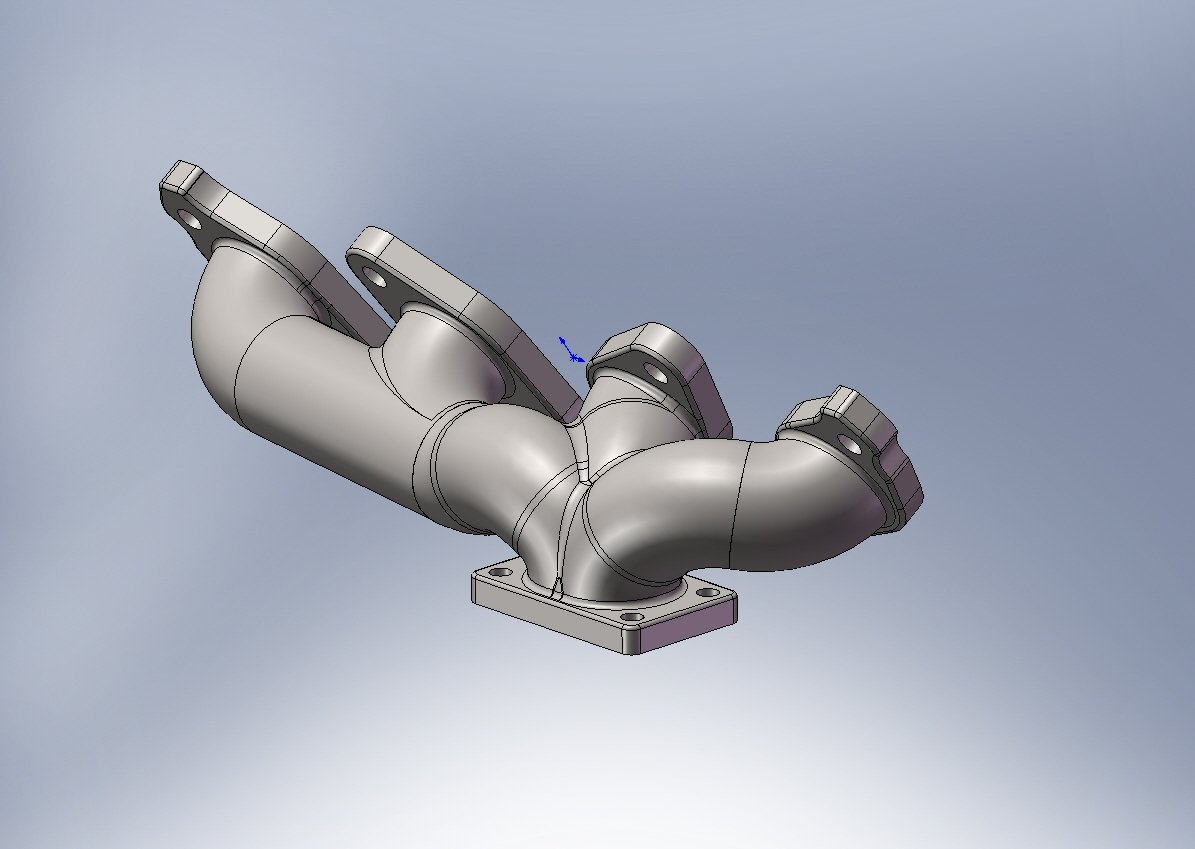

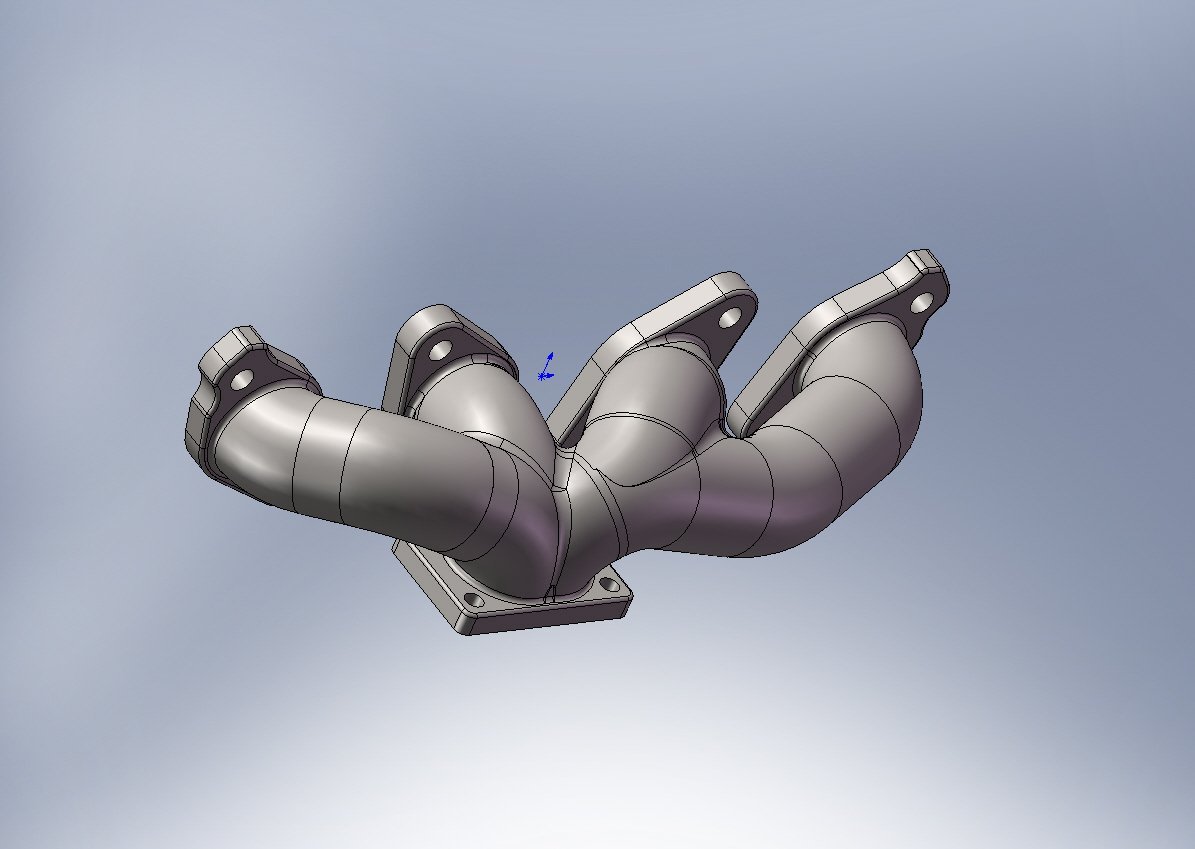

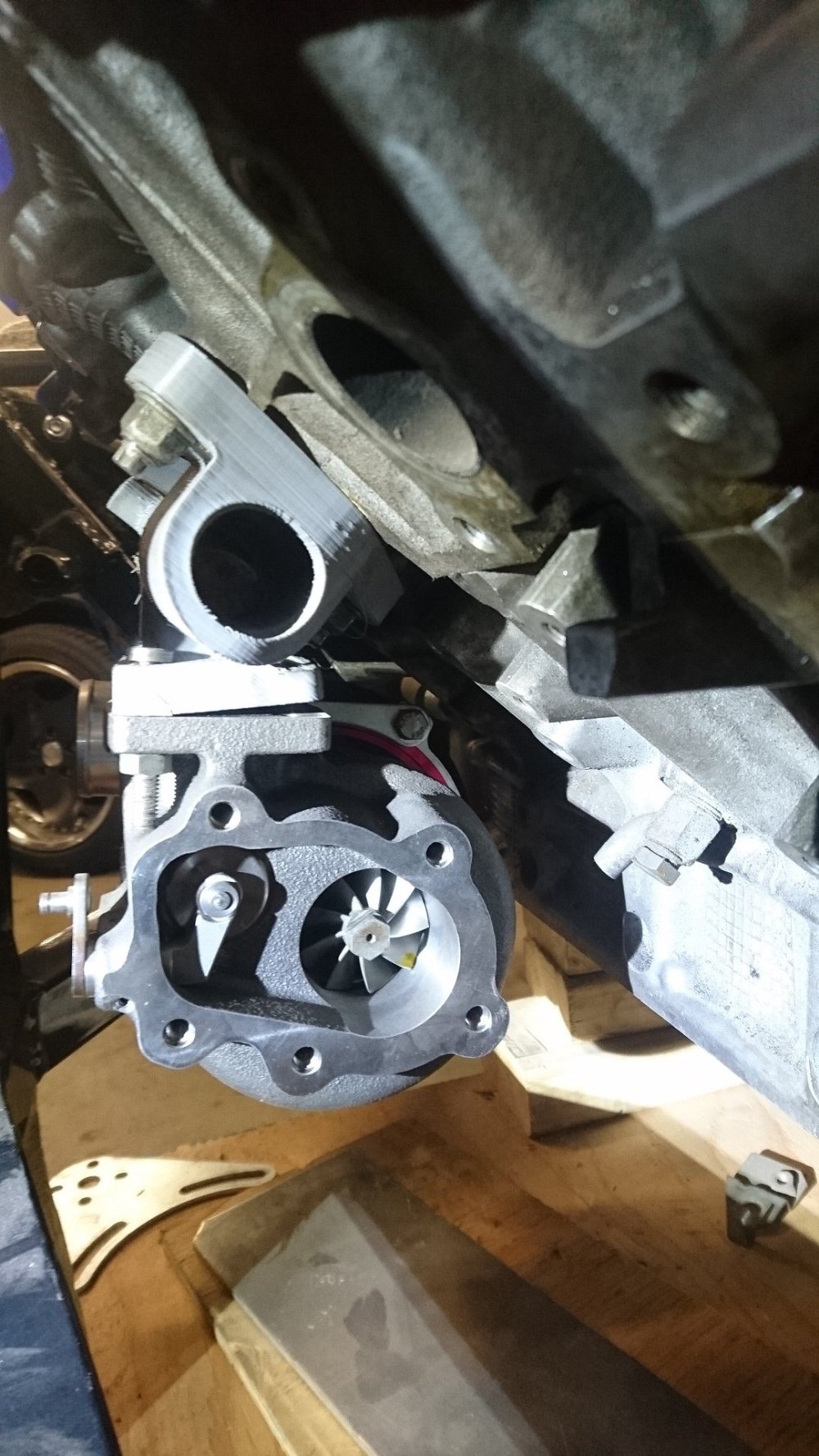

and he is using a 1UZ-FE engine with twin turbos in it.

As a joke I said I would get him some twin turbo cast iron turbo manifolds and he jumped

on that, imagine my chagrin when I found out that nobody makes this.

So, for the last year I have been searching for a foundry that is willing to make some, I have

found a foundry in Turkey but the minimum order is 10 pairs, so 20 manifolds in total.

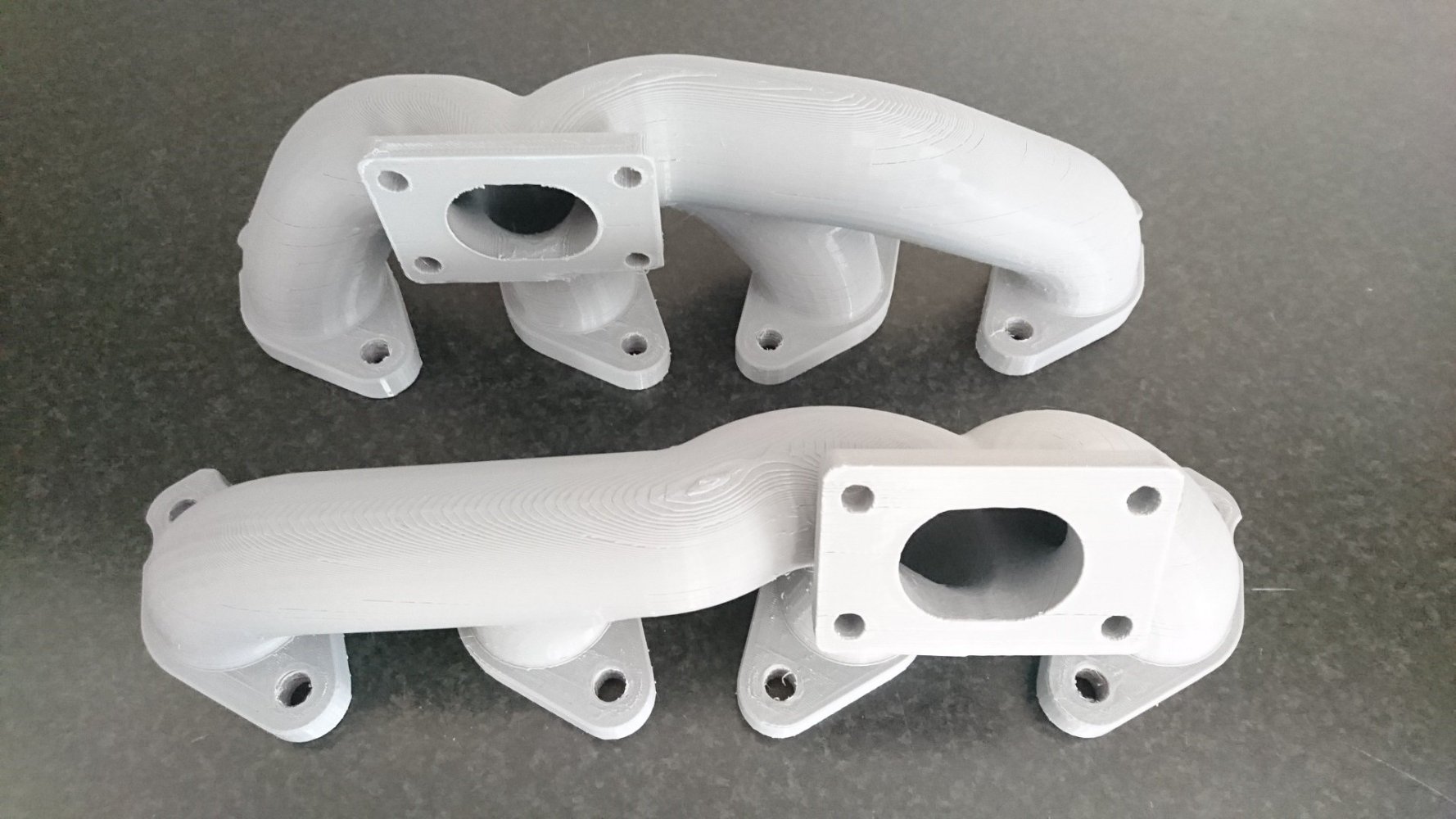

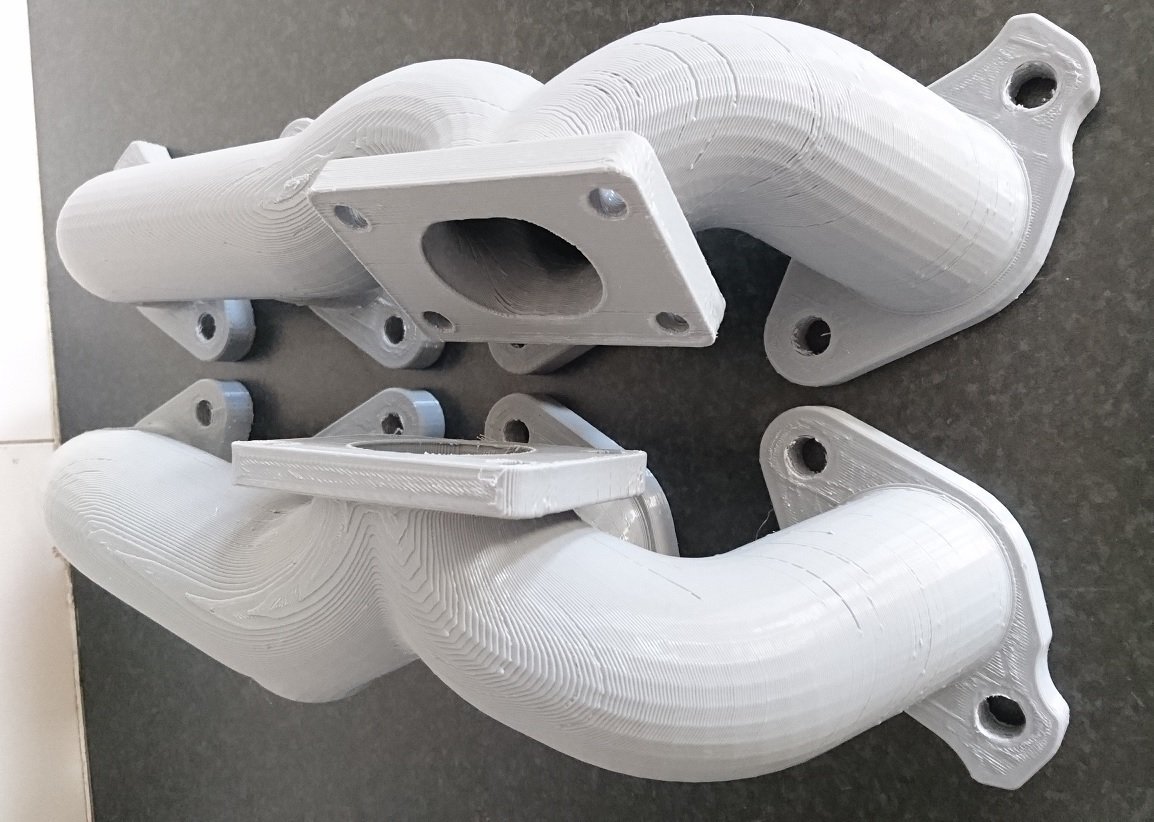

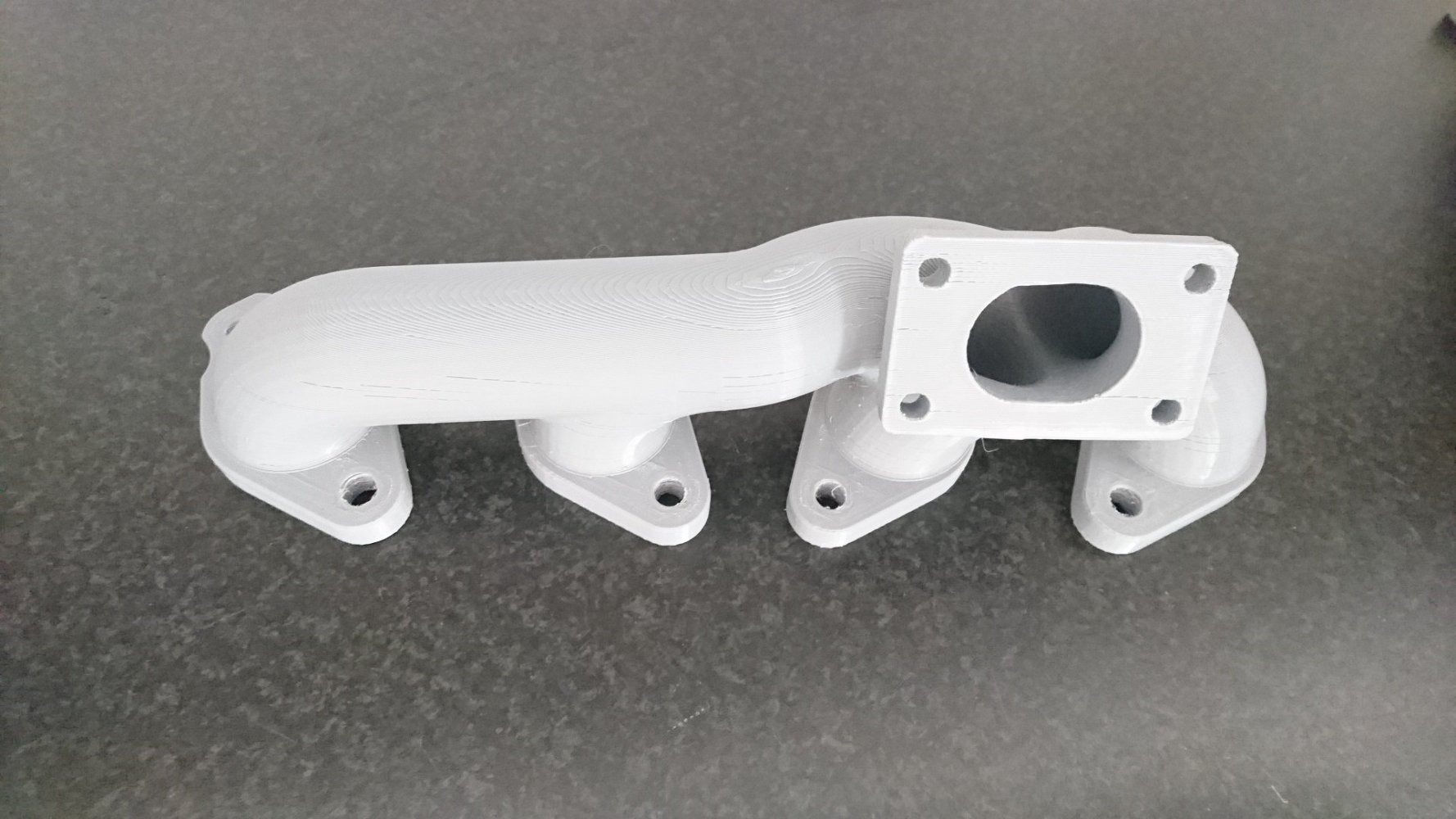

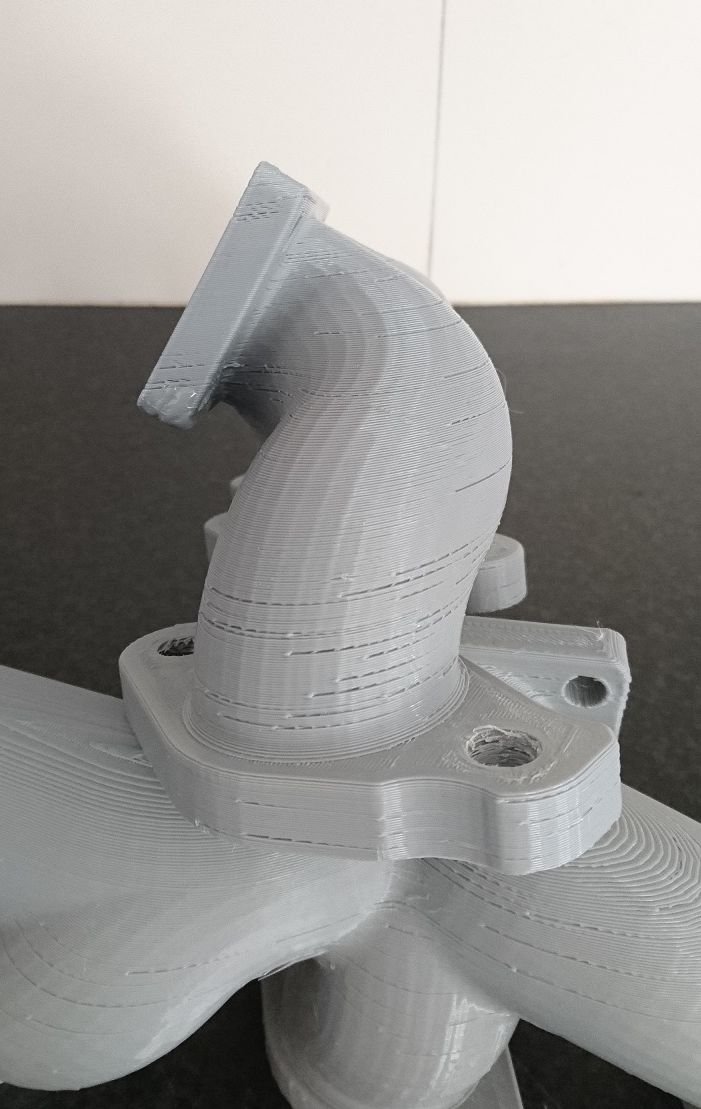

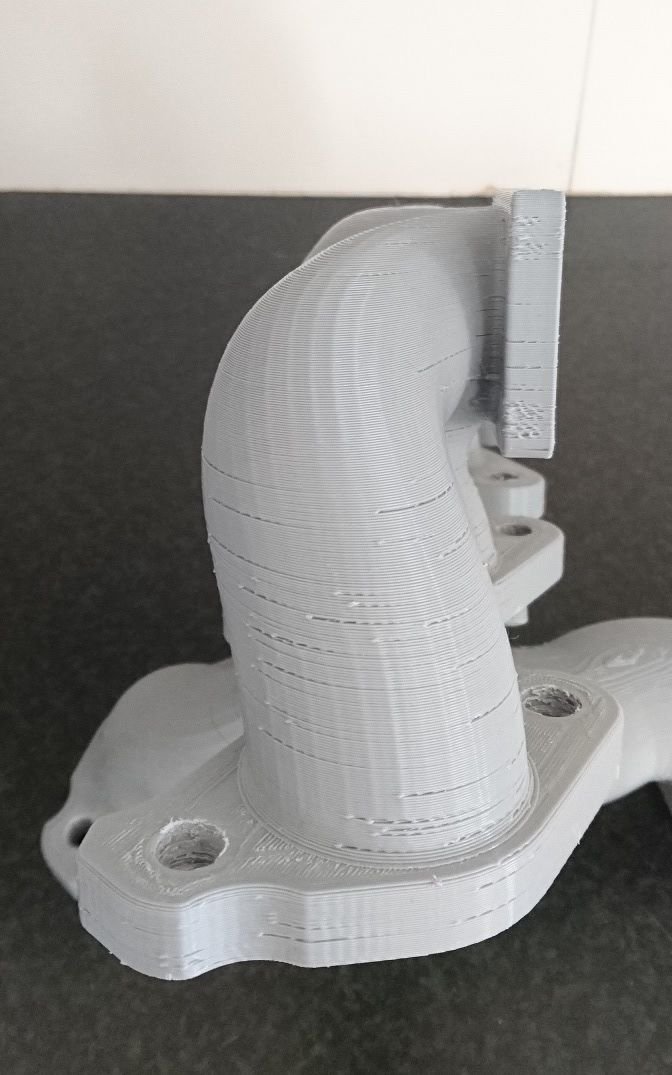

I have tested some early 3D printed versions of the manifolds in his kit car and they are as a

tight fit as I can make them, there is no space in that engine room!

The design of the right side manifold is done. There is still some work to do on the left side

manifold.

The center of the left T25 turbo flange is placed 80 mm behind the center of cylinder 2 and 3,

the center of the right T25 turbo flange is placed 59 mm behind the center of cylinder 2 and 3,

this is done to compensate for the 21 mm offset between the sides.

It also places the turbos symmetrical VS the block and the engine mount flanges.

I looked into placing the turbos in the center between cylinder 2 and 3, but the outside of the

compressor housing comes into conflict with the engine mount flanges on the block.

The two turbos we have tested is Garrett GTX2867R clones, with T25 inlet flange and integrated

wastegate.

I think Mitsubishi TD04HL-19T turbos should fit, it looks like they are slightly smaller than the

Garrett ones.

The alloy will be EN-GJSA-XNi22/S-Ni22/S-Ni22 cast steel alloy, an alloy often used for turbo

turbine housings.

Is there any interest in this?

Been a while since i have been around but, just as I thought I was out I get dragged back in.

A friend of mine is building a kit car, a cobra mk4 replica from Gardner Douglas gdcars.com

and he is using a 1UZ-FE engine with twin turbos in it.

As a joke I said I would get him some twin turbo cast iron turbo manifolds and he jumped

on that, imagine my chagrin when I found out that nobody makes this.

So, for the last year I have been searching for a foundry that is willing to make some, I have

found a foundry in Turkey but the minimum order is 10 pairs, so 20 manifolds in total.

I have tested some early 3D printed versions of the manifolds in his kit car and they are as a

tight fit as I can make them, there is no space in that engine room!

The design of the right side manifold is done. There is still some work to do on the left side

manifold.

The center of the left T25 turbo flange is placed 80 mm behind the center of cylinder 2 and 3,

the center of the right T25 turbo flange is placed 59 mm behind the center of cylinder 2 and 3,

this is done to compensate for the 21 mm offset between the sides.

It also places the turbos symmetrical VS the block and the engine mount flanges.

I looked into placing the turbos in the center between cylinder 2 and 3, but the outside of the

compressor housing comes into conflict with the engine mount flanges on the block.

The two turbos we have tested is Garrett GTX2867R clones, with T25 inlet flange and integrated

wastegate.

I think Mitsubishi TD04HL-19T turbos should fit, it looks like they are slightly smaller than the

Garrett ones.

The alloy will be EN-GJSA-XNi22/S-Ni22/S-Ni22 cast steel alloy, an alloy often used for turbo

turbine housings.

Is there any interest in this?

Attachments

Last edited: