Head Sealing & O-Ringing

- Thread starter cribbj

- Start date

The 1UZFE EGR Delete Kit is available for sale here.

Yup they told me they only offered it in .051" thickness and the Tech rep told me it would cost like $600 i dont remember the exact price, I called (440)354-0777 and asked for the tech rep cause i wasnt sure if it was a whole new gasket or if they were just adding the phuzion rings to the mls gasket, but now its actually a complete drop in gasket..

No, not if you take the time and effort to seal everything up at assembly time. You will notice remnants of Loctite Gray Silicon sealer. The best stuff ever . I use it conservatively but correctly. It seals the rings to the block, the gasket and of course around all the water passages. The copper gasket is annealed before hand and is surprisingly pliant and takes up a lot of undulations where necessary. The silicon sealer is still required though.

We have run a little four banger to 18 psi boost already, 500 odd engine hp . The bearings don't last though..

The V6 engines are pressurized to 20 odd psi regularly. Remember that the Alfa has brilliant studs that go way down deep beside the sleeves .There is thankfully no problems as in the Lexus motor..

I use stainless but its a bugger to machine.

Absolutely it can. I have looked at the possibility already. Just need to figure a way of enlarging the tripple plate gasket without burrs and other nasty stuff. My solution to date would be a top and bottom sandwich plate on a nc mill.. It works for the copper ..

No need to re weld them. They are re usable . Once the groove is in the head the rings simply align themselves back into them. The rings have to remain cylinder specific though. Remember the sealant though. I usually give the torque wrench a few Nm extra on re used rings..5 or so..

John, sorry, my reply did not work as I had intended but it is all there..

Alex,

x= 3.5mm to 4mm-this is not a critical dia.

x2= would be the above minus the 0.5mm to 0.8 mm dedicated to the "spike"

The "spike" base is 0.5 to 0.8 mm-x2 will change accordingly.

There is no second step as depicted by y1 , only y2.

Y1 is 0.2 to 0.3 mm larger than the groove you machine into the top of your sleeve. This gets forced into the copper gasket and re creates the std sealing method.

The "spike" height will be the thickness of the copper gasket plus 0.3mm that is forced into the head material.

Hope Ive covered it all..

No worries mate, I fixed it the way I think you wanted it

And by the way, big thanks to Kriss, Ben, Alex, Carlos and everyone else who's asking good questions and posting good info in this thread. That's what this forum is all about; free exchange of good information and helping each other.

A good message, and another freebie for you guys who don't like to share your secrets......

Im concerned about applying too much force to the ring while on the lathe, and the only lathe i have access to is in my school its from like ww2 and it doesnt cut perfect, and i only have one blade that can cut steel lol..

i will be buying MLS gaskets soon and the 10mm lextreme ARP head studs I wanna be ready to boost 20+ psi im on a budget so im relying purely on boost to get the numbers up, Im a highschool student so once i have money i can build an engine outside the right way, and drop it in. I need tips on what I can do at the moment to try and seal this sucker up till im ready to, keep in mind im ballin on a budget

Tune is what keeps these things from going bad...

TTY head bolts don't hold up after many heat cycles with F/I it seems...

I read on the arp site on theyre torque chart and 70-75ft.lbs was the recommended torque torque.. and yea I also read they recommend they're torque lube..

The seal I saw was on speedys link to a pontiac site that showed the o ringing process they were applying it to the gaskets around the water holes it resembled metallic RTV silicone

CarlosR347

New Member

Calros, I'm a little bit confused that you have got a positive feedback from Cometic about our 1UZ head gasket. I charge a friend in the USA to ask Cometic for the Phuzion HG for the 1UZ and they told him they can not offer the Phuzion for this engine.

Yes, you are right it's very nice to have the machining tools. I thought I could spend 2500-3000 bucks for this machines first and can do a lot of work myself before I have to pay for every part that I need.

Alex

Yup they told me they only offered it in .051" thickness and the Tech rep told me it would cost like $600 i dont remember the exact price, I called (440)354-0777 and asked for the tech rep cause i wasnt sure if it was a whole new gasket or if they were just adding the phuzion rings to the mls gasket, but now its actually a complete drop in gasket..

Nice solution Kriss. Do you have any issues with coolant weepage with the copper head gaskets?

How much boost have you run with these?

What are your custom sealing rings made of?

I wonder if something like this could be adapted to work with the OEM head gasket, or even the Cometic MLS's to improve their performance?

Once the head is torqued with your rings, can it be reused? Have you welded them and reused them?

How much boost have you run with these?

What are your custom sealing rings made of?

I wonder if something like this could be adapted to work with the OEM head gasket, or even the Cometic MLS's to improve their performance?

Once the head is torqued with your rings, can it be reused? Have you welded them and reused them?

Speeedy

Member

Hey BigKriss,

that's a very good idea! Many thanks for your pics. But I have some questions.

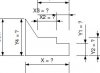

I add a drawing where I show the profile of your seal ring like I understand it from the pictures. Please correct it if I'm wrong. Maybe you would give us some dimensions I marked in the drawing to give me (or us) a better insight.

Thanks

Alex

that's a very good idea! Many thanks for your pics. But I have some questions.

I add a drawing where I show the profile of your seal ring like I understand it from the pictures. Please correct it if I'm wrong. Maybe you would give us some dimensions I marked in the drawing to give me (or us) a better insight.

Thanks

Alex

Attachments

Nice solution Kriss. Do you have any issues with coolant weepage with the copper head gaskets

No, not if you take the time and effort to seal everything up at assembly time. You will notice remnants of Loctite Gray Silicon sealer. The best stuff ever . I use it conservatively but correctly. It seals the rings to the block, the gasket and of course around all the water passages. The copper gasket is annealed before hand and is surprisingly pliant and takes up a lot of undulations where necessary. The silicon sealer is still required though.

How much boost have you run with these?

We have run a little four banger to 18 psi boost already, 500 odd engine hp . The bearings don't last though..

The V6 engines are pressurized to 20 odd psi regularly. Remember that the Alfa has brilliant studs that go way down deep beside the sleeves .There is thankfully no problems as in the Lexus motor..

What are your custom sealing rings made of?

I use stainless but its a bugger to machine.

I wonder if something like this could be adapted to work with the OEM head gasket, or even the Cometic MLS's to improve their performance?

Absolutely it can. I have looked at the possibility already. Just need to figure a way of enlarging the tripple plate gasket without burrs and other nasty stuff. My solution to date would be a top and bottom sandwich plate on a nc mill.. It works for the copper ..

Once the head is torqued with your rings, can it be reused? Have you welded them and reused them?

No need to re weld them. They are re usable . Once the groove is in the head the rings simply align themselves back into them. The rings have to remain cylinder specific though. Remember the sealant though. I usually give the torque wrench a few Nm extra on re used rings..5 or so..

Last edited by a moderator:

CarlosR347

New Member

Kriss thats pretty cool,im assuming you used steel for the rings? and when u do this and cut into the head would resurfacing the head remove the indentation cut from the ring?, how hard would it be to make these on a lathe? im really considering this in conjunction with cometic MLS, maybe if I ordered the gaskets like 2mm larger in Diameter which will allow the ring to fit snug inside it, oh by the way if we were to machine a slight sharp edge on the bottom to cut slightly into the aluminum 1uz block?

Hey BigKriss,

that's a very good idea! Many thanks for your pics. But I have some questions.

I add a drawing where I show the profile of your seal ring like I understand it from the pictures. Please correct it if I'm wrong. Maybe you would give us some dimensions I marked in the drawing to give me (or us) a better insight.

Thanks

Alex

John, sorry, my reply did not work as I had intended but it is all there..

Alex,

x= 3.5mm to 4mm-this is not a critical dia.

x2= would be the above minus the 0.5mm to 0.8 mm dedicated to the "spike"

The "spike" base is 0.5 to 0.8 mm-x2 will change accordingly.

There is no second step as depicted by y1 , only y2.

Y1 is 0.2 to 0.3 mm larger than the groove you machine into the top of your sleeve. This gets forced into the copper gasket and re creates the std sealing method.

The "spike" height will be the thickness of the copper gasket plus 0.3mm that is forced into the head material.

Hope Ive covered it all..

Speeedy

Member

Kriss,

perfect!! Thanks for the details.

Thanks for the details.

But I was unaware that you machine your sleeves too. Now things have come full circle.

It's a good solution but there is a lot of work to do before.

The Helicoflex O-ring is a "put all together on stock block and heads, torque your studs and be happy- solution".

But nobody here has experience with that gas-filled O-rings and we don't know if it's work under high boost.

The future will show the answer.

Alex

perfect!!

But I was unaware that you machine your sleeves too. Now things have come full circle.

It's a good solution but there is a lot of work to do before.

The Helicoflex O-ring is a "put all together on stock block and heads, torque your studs and be happy- solution".

But nobody here has experience with that gas-filled O-rings and we don't know if it's work under high boost.

The future will show the answer.

Alex

Last edited by a moderator:

John, sorry, my reply did not work as I had intended but it is all there..

No worries mate, I fixed it the way I think you wanted it

And by the way, big thanks to Kriss, Ben, Alex, Carlos and everyone else who's asking good questions and posting good info in this thread. That's what this forum is all about; free exchange of good information and helping each other.

A good message, and another freebie for you guys who don't like to share your secrets......

Last edited:

XR8tt

Active Member

Upgrading to larger head studs will go along way to sealing... Weak bolts results in head lifting...

A wire grove just behind fire ring on graphite gasket can hold plenty ..

On my Dart block Ford turbo engine it has 1/2 studs .9 stainless steel mig wire in a grove on head.. .030 copper gaskets, O rings around water passages etc..

With light silicon on BOTH sides of gasket, heads and block...

Run up to 22Lb boost at near 850 h.p...

BUT with Cometic gaskets which are much stronger.. It seems any issues?? Is with bolts stretching and heads lifting...

A wire grove just behind fire ring on graphite gasket can hold plenty ..

On my Dart block Ford turbo engine it has 1/2 studs .9 stainless steel mig wire in a grove on head.. .030 copper gaskets, O rings around water passages etc..

With light silicon on BOTH sides of gasket, heads and block...

Run up to 22Lb boost at near 850 h.p...

BUT with Cometic gaskets which are much stronger.. It seems any issues?? Is with bolts stretching and heads lifting...

CarlosR347

New Member

Hey what would you guys think about this, its just something I pictured while sitting in English class  ? I figured this ring could be fitted snug in the bore Diameter of a larger MLS HG for example if the inside Dia. of the ring is 88mm outside is 92mm then maybe the 3UZ(91mm bore) mls HG would work (assuming the HG is slightly larger in Dia).. the thickness would match the MLS HG of .051" or maybe .050"-.049" to focus more pressure on the actual MLS rather than on the Ring seating face (my theory is that the MLS will recieve the full torque and the ring will be under maybe 90-80% torque, Im assuming this will help keep the water in its place and reduce stress points in the head because once the engine warms up the Ring will be exposed to much higher temps than the gasket itself so it will grow a bit).. Id think using steel will be easier to machine and will have a closer thermal expansion rate of the one the MLS has.. Sorry about the crappy Art skills

? I figured this ring could be fitted snug in the bore Diameter of a larger MLS HG for example if the inside Dia. of the ring is 88mm outside is 92mm then maybe the 3UZ(91mm bore) mls HG would work (assuming the HG is slightly larger in Dia).. the thickness would match the MLS HG of .051" or maybe .050"-.049" to focus more pressure on the actual MLS rather than on the Ring seating face (my theory is that the MLS will recieve the full torque and the ring will be under maybe 90-80% torque, Im assuming this will help keep the water in its place and reduce stress points in the head because once the engine warms up the Ring will be exposed to much higher temps than the gasket itself so it will grow a bit).. Id think using steel will be easier to machine and will have a closer thermal expansion rate of the one the MLS has.. Sorry about the crappy Art skills

Carlos, good idea as well. Delete the lower tooth and it will work 100 %. The most critical part here is to get the balance between sealing properly and sealing the rest of the gasket around the water sections.

If you`re using the standard type graphite gasket, you should not really have an issue as this type of gasket has plenty of "give"..

There is an Italian made gasket that is based on your rendition above for the Alfa and also for Lancia engines amongst others. The name eludes me right now but it is four loose stainless rings with an outer gasket setup.

This type of gasket work very well and does away with the machining of the reciever groove in the sleeves or block. It also takes away the std. sealing method as per my setup..I hjust like the double whammy seal of my setup.

Alfa Romeo used pressure gas filled "cooper" type rings as far back as the 70`s on the production Alfa Romeo Turbodelta engine. I still have a set of these but purely for nostalgic purposes.

I have also experimented with copper wire "o" rings into the head as well as the sleeves. The wire ring has to clamp around the outer circumference of the fire ring built into the std. gasket.

Now I have seen some real nasty v8 gaskets that are simply a piece of cardboard with a folded sheet of real thin metal around each bore. This will not suffice. The better the quality gasket you start off with, the more successful the endeavor will be.

Just looking at your picture again, always remember that steel penetrates ally best. Trying to force the tooth into cast iron will not work with torque`ing alone. Machining a reciever groove will work best.

If you`re using the standard type graphite gasket, you should not really have an issue as this type of gasket has plenty of "give"..

There is an Italian made gasket that is based on your rendition above for the Alfa and also for Lancia engines amongst others. The name eludes me right now but it is four loose stainless rings with an outer gasket setup.

This type of gasket work very well and does away with the machining of the reciever groove in the sleeves or block. It also takes away the std. sealing method as per my setup..I hjust like the double whammy seal of my setup.

Alfa Romeo used pressure gas filled "cooper" type rings as far back as the 70`s on the production Alfa Romeo Turbodelta engine. I still have a set of these but purely for nostalgic purposes.

I have also experimented with copper wire "o" rings into the head as well as the sleeves. The wire ring has to clamp around the outer circumference of the fire ring built into the std. gasket.

Now I have seen some real nasty v8 gaskets that are simply a piece of cardboard with a folded sheet of real thin metal around each bore. This will not suffice. The better the quality gasket you start off with, the more successful the endeavor will be.

Just looking at your picture again, always remember that steel penetrates ally best. Trying to force the tooth into cast iron will not work with torque`ing alone. Machining a reciever groove will work best.

CarlosR347

New Member

Yea in my head it all made sense for it to cut into the aluminum block but I now remember the sleeves extend around that area, hey Kriss how hard is it to make these rings?

CarlosR347

New Member

It is not that easy, scrapped quite a few in the learning stages. I made jigs and use a thin wall pipe to start off with. Often as you are parting the ring it grabbs and is fubarred..Thats life.

Im concerned about applying too much force to the ring while on the lathe, and the only lathe i have access to is in my school its from like ww2 and it doesnt cut perfect, and i only have one blade that can cut steel lol..

i will be buying MLS gaskets soon and the 10mm lextreme ARP head studs I wanna be ready to boost 20+ psi im on a budget so im relying purely on boost to get the numbers up, Im a highschool student so once i have money i can build an engine outside the right way, and drop it in. I need tips on what I can do at the moment to try and seal this sucker up till im ready to, keep in mind im ballin on a budget

stevechumo

Active Member

I've been boosting and using Cometic MLS had gaskets with ARP studs fine. I intially had coolant leakage, but the block holds perfectly fine after I re-torqued it. I think MLS gaskets need to be re-torqued just like copper gaskets.

XR8tt

Active Member

Yes as with most engines with forced induction !!!I've been boosting and using Cometic MLS had gaskets with ARP studs fine. I intially had coolant leakage, but the block holds perfectly fine after I re-torqued it. I think MLS gaskets need to be re-torqued just like copper gaskets.

Tune is what keeps these things from going bad...

TTY head bolts don't hold up after many heat cycles with F/I it seems...

CarlosR347

New Member

The torque for the 10mm ARP studs is upto 75ftlbs I wonder if they would he 80ft.lbs.. and I notice ppl use some kind of sealant on copper hg can it be used with the mls to aid sealing?

XR8tt

Active Member

Yes there's some copper spray sealant in can. It stays rather sticky and doesn't seem to harden...

Imo if your serious thicker head studs would help...

But I would say ARP at 10mm would far better than std TTY bolts..

Make sure washer, threads are well lubricated...

There are different torque specs between oil and Molly grease...

Check with ARP on 10mm stud ?? You maybe going beyond the studs threshold...

You have to consider the strength of bolt in alloy too...

Imo if your serious thicker head studs would help...

But I would say ARP at 10mm would far better than std TTY bolts..

Make sure washer, threads are well lubricated...

There are different torque specs between oil and Molly grease...

Check with ARP on 10mm stud ?? You maybe going beyond the studs threshold...

You have to consider the strength of bolt in alloy too...

CarlosR347

New Member

Yes there's some copper spray sealant in can. It stays rather sticky and doesn't seem to harden...

Imo if your serious thicker head studs would help...

But I would say ARP at 10mm would far better than std TTY bolts..

Make sure washer, threads are well lubricated...

There are different torque specs between oil and Molly grease...

Check with ARP on 10mm stud ?? You maybe going beyond the studs threshold...

You have to consider the strength of bolt in alloy too...

I read on the arp site on theyre torque chart and 70-75ft.lbs was the recommended torque torque.. and yea I also read they recommend they're torque lube..

The seal I saw was on speedys link to a pontiac site that showed the o ringing process they were applying it to the gaskets around the water holes it resembled metallic RTV silicone

Similar threads

- Replies

- 0

- Views

- 678

- Replies

- 1

- Views

- 1K

- Replies

- 2

- Views

- 890

- Replies

- 0

- Views

- 709