xirforever

New Member

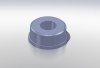

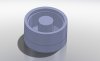

Okay, so I made some delrin bushings for my subframe a while ago (SC400), and while they were and improvement, I don't feel they are exactly what I wanted - a hard poly insert. So I have my entire rear end pulled apart and I thought while I was repainting everything, I would pull those delrin inserts out, and make some poly ones to go in. Well my last experience machining poly for my engine mounts was not my favorite, so I thought, why not machine a mold, and cast them? I had some extra delrin laying around and I decided to draw up a mold, and start making it. The mold will be two or three piece in design so I can actually get the urathane out when done. I made the lower half today.

I figure I will buy some of the polyurathane resin from McMaster and try that out with a hardness of 80 shore A. Id prefer 85-90 but its not available and I just bought some 100 and you might as well call it delrin it is so hard. I will probably buy some mold release and pour it in very slowly when I am ready. Does anyone have any experience with this sort of thing? Any advice?

I figure I will buy some of the polyurathane resin from McMaster and try that out with a hardness of 80 shore A. Id prefer 85-90 but its not available and I just bought some 100 and you might as well call it delrin it is so hard. I will probably buy some mold release and pour it in very slowly when I am ready. Does anyone have any experience with this sort of thing? Any advice?